Laboratory of Low Temperature Science is in the building of Center for Low Temperature Science (CLTS) in Katahira campus

History of liquefiers

Liquefiers in Tohoku University (Katahira cpampus)

The first helium liquefier in Japan was installed in 1952 at the Low Temperature Lobratory (the predecessor of Center for Low Temperature Science at present), in Institute for Materials Research (IMR), Tohoku University. This was the start of the low temperature science researches in Japan. The liquefier now working in this center is the fourth generation. Here, we briefly introduce the helium liquefiers in the past and now in Tohoku University.

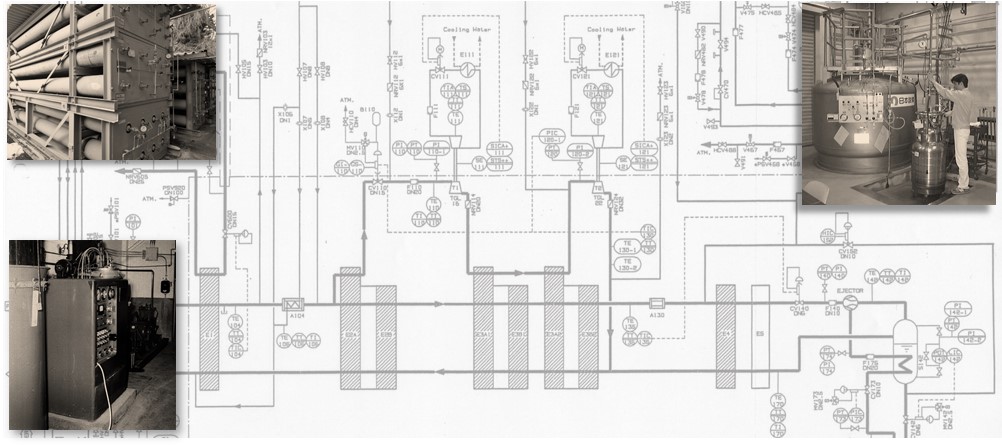

ADL Collin's type liquefier (First Helium Liquefier in Japan: 1952-1970)

According to the early recognition about the importance of material research at low temperatures, IMR introduced the Collins-type

helium liquefier (made by A.D. Little Ltd., USA) for the first time in Japan in 1952. This machine, having a liquefaction capacity

of 4 liters/h at that time, made a great many contributions to the developments of low-temperature scientific researches not only at

Tohoku University but also in Japan. Later the capacity was raised up to 8 liters/h due to the addition of a compressor.

According to the early recognition about the importance of material research at low temperatures, IMR introduced the Collins-type

helium liquefier (made by A.D. Little Ltd., USA) for the first time in Japan in 1952. This machine, having a liquefaction capacity

of 4 liters/h at that time, made a great many contributions to the developments of low-temperature scientific researches not only at

Tohoku University but also in Japan. Later the capacity was raised up to 8 liters/h due to the addition of a compressor.

(Total amount of liquefaction: 21,300 liters, Average:800 liters/year)

Nippon Sanso LHE60 (1971-1992)

In order to satisfy the demands

of liquid helium (L. He) from the many users in Tohoku University, which had increased year by year, Cryogenic Center was organized from

the section of helium liquefaction in IMR with a renewal of the liquefier. The second liquefier, made by Nippon Sanso

K.K., Japan, had a capacity of 60 liters/h with the reciprocal expansion engines and a external helium gas purifier. According

to this replacement, the supply of L. He to all the laboratories and the faculties became possible.

(Total amount of liquefaction: 1,132,600 liters, Average: 38,000 liters/year)

Linde TCF 50 (1993-2009)

Due to the frequent machine troubles after use of more than 20 years and the further increase in the demands of L. He, the new powerful

liquefier was desired. Thanks to the great efforts of the related staffs, the liquefier was renewed again in 1992. The

third machine, TCF 50, made by Linde Cryogenics LTD., had a capacity of 150 liters/h, which was 2.5 times higher than

the pervious one, with the gas bearing turboexpanders and a internal gas purifier.

Athough small troubles sometimes started to happen from 2006, the system had been continuing

the stable supply of L. He with 155,000 liters/year maximum until 2009.

(Total amount of liquefaction: 1,556,000 liters, Average: 97,000 liters/year)

Linde L280S (2010-2021)

Because of the demands of L. He that continued increasing, the helium liquefying facilities with higher performance had been necessary.

Fortunately the budgetary request for them was accepted in 2009, and we renewed the system having the L280 liquefier

with a capacity of 200 liters/h as a main facility. This system is also equipped with a liquid helium pump, which enables us to transfer 100L

liquid helium into a carrying container in 5 minutes, leading to shortening of time for delivery service. However, it has been tuned out for a while

that the internal purifier of the fourth machine is not so effective for the removal of hydrogen,

resulting in the serious problem that the liquid helium is contaminated by

particles of solid hydrogen. Then, the liquefaction was continued using devising operational methods, such as purging the high-pressure line before cooling. Eventually we installed an external hydrogen removal device in FY2020.

Because of the demands of L. He that continued increasing, the helium liquefying facilities with higher performance had been necessary.

Fortunately the budgetary request for them was accepted in 2009, and we renewed the system having the L280 liquefier

with a capacity of 200 liters/h as a main facility. This system is also equipped with a liquid helium pump, which enables us to transfer 100L

liquid helium into a carrying container in 5 minutes, leading to shortening of time for delivery service. However, it has been tuned out for a while

that the internal purifier of the fourth machine is not so effective for the removal of hydrogen,

resulting in the serious problem that the liquid helium is contaminated by

particles of solid hydrogen. Then, the liquefaction was continued using devising operational methods, such as purging the high-pressure line before cooling. Eventually we installed an external hydrogen removal device in FY2020.

(Total amount of liquefaction: 1,552,699 liters, Average: 133,088 liters/year)

Linde L280 (2022-present)

The former liquefier, which had been operated at a high operating rate with an annual supply of 100,000 to 160,000 liters, began to show frequent minor failures from its ninth year (2018). Thanks to the great cooperation of the administrative staff and related researchers in the university, our budget request was approved and we were able to update the liquefaction system containing L280 liquefierwith a capacity of 230 liters/h as the main equipment. The liquefier has the same model name as the former one, but the liquefaction turbine expansion engine has been improved, and a filter has been added to the internal purifier to remove hydrogen, which was a problem in the past. The features of new system are as following: (1) we can choose between two liquefaction modes: ejector (EJ) mode and JT mode for the liquefier, (2) the helium pumping system becomes fully automatic, (3) the storage capacity is improved by installing two 5000L liquid helium storage tanks, and (4) liquefaction efficiency is improved by improving purification mode and adopting an inverter-equipped compressor.

The former liquefier, which had been operated at a high operating rate with an annual supply of 100,000 to 160,000 liters, began to show frequent minor failures from its ninth year (2018). Thanks to the great cooperation of the administrative staff and related researchers in the university, our budget request was approved and we were able to update the liquefaction system containing L280 liquefierwith a capacity of 230 liters/h as the main equipment. The liquefier has the same model name as the former one, but the liquefaction turbine expansion engine has been improved, and a filter has been added to the internal purifier to remove hydrogen, which was a problem in the past. The features of new system are as following: (1) we can choose between two liquefaction modes: ejector (EJ) mode and JT mode for the liquefier, (2) the helium pumping system becomes fully automatic, (3) the storage capacity is improved by installing two 5000L liquid helium storage tanks, and (4) liquefaction efficiency is improved by improving purification mode and adopting an inverter-equipped compressor.

At the same time as the introduction, the global pandemic of the new coronavirus infection and global helium procurement difficulties coincided, and construction work and parts procurement were not progressing as planned, making it doubtful that the project would be completed within the deadline. We are fortunate that the update was completed without delay thanks to the dedicated efforts of the related persons both inside and outside the university, including center technical staff, university administration, and suppliers. Although there were some small initial troubles just after instalation, the liquid helium has been stabely supplied since April 2022.